Collagen casings (edible and non-edible) for fresh and cooked sausages

Our collagen casings, available in both edible and non-edible formats, as well as single- and multilayer plastic casings that are permeable or non-permeable, are the perfect solution for packaging a wide range of meat products.

From fresh sausages to roasted specialties like mortadella, from braised meats such as carne salada to pre-cooked products like cotechino, every recipe made with high-quality ingredients deserves a dedicated casing that enhances freshness, flavor, and presentation.

At HS Casings, we develop innovative packaging solutions designed to ensure safety, versatility, and performance for both traditional and modern food applications.

Our collagen casings for sausages and meat products are ideal for:

- Fresh sausage (such as the traditional luganiga)

- Hotdogs and frankfurters

- Mini salami

- Meat snacks

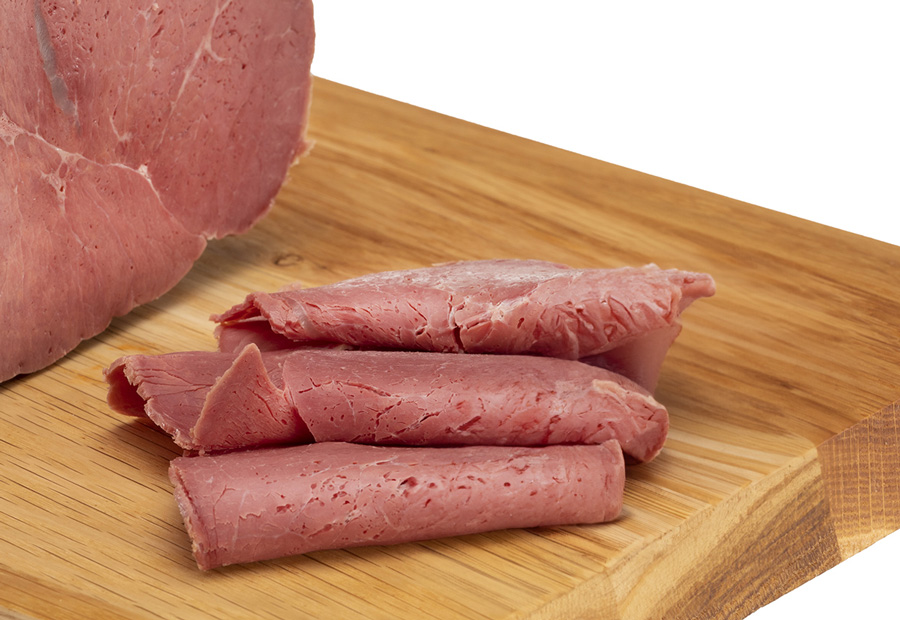

- Sliced products

- Cured meats

- Pet food

- Fish-based products

- Plant-based foods (seitan, tempeh)

With HS Casings, you can rely on high-quality casings that preserve your product’s authentic taste while ensuring a flawless presentation from production to the consumer’s table.

Our solutions for

Fresh and cooked sausages

Edible collagen casings and film

Edible collagen casings are a naturally occurring material that is practically sterile and is made by extraction from the skins of cattle. Available in straight versions in sizes ranging from 13mm to 45mm, or curved versions in sizes ranging from 20mm to 45mm

The casings are ready to use (no soaking required), already shirred into a stick in various lengths to meet the customer’s specific needs (such as the number of pieces or the final weight determined by the length of the stick).

They meet all European standards for foodstuffs.

They are ideal for manufacturers of fresh sausage (such as “luganiga”) frankfurter sausages, mini salamis andmeat snacks.

These casings offer the following benefits:

- optimum adaptation to the use of machinery (the finished product is always consistent in terms of its diameter and firmness)

- superior productivity and profitability (less downtime; increased filling and production speed compared to natural casings)

- lower labour costs (fewer manual workers required)

- optimum presentation of the finished product thanks to the uniformity of the casing

Special single-layer tubular casings

Polyamide materials that are totally impermeable to smoke and steam. Generally used for products demanding a cylindrical shape or other format (using special moulds in the latter case), such as: . . .

- in the meat industry: cooked products that do not require smoking (“Lyoner” sausage and variations, pâté, ham cooked in moulds and regenerated, and mortadella)

- for stretched processed cheeses

- for the production of organic and wholemeal food products

- for semi-processed food products, and when a specific product shape is required in general (sliced cooked sausages, meat or other stuffing for pasta manufacturers, processed cheese, stuffing for pasta, maize polenta, gnocchi alla romana, lard etc)

- for industrial use in-house (when the tubular casing is used during production before being removed).

Special multilayer tubular casings

Casings made from special polymers (three or five layers) made up into a permeable or impermeable tubular format. Special tubular casings are available for smoking.

Available in size 50 to size 120, coloured, shirred, clipped or tied to size, in rolls or skeins, with the option of printing in up to 6 colours.

They differ to single layer tubular casings on account of the following specifications:

- shrinking capacity

- superior mechanical resistance and optimum adaptation to the use of machinery

- no weight loss

- maximum conservation of the product even without vacuum packing with the special opaque version

- can be sterilized

- casing peels away perfectly

- glossy casing

They meet all European legal standards for materials coming into contact with foodstuffs.