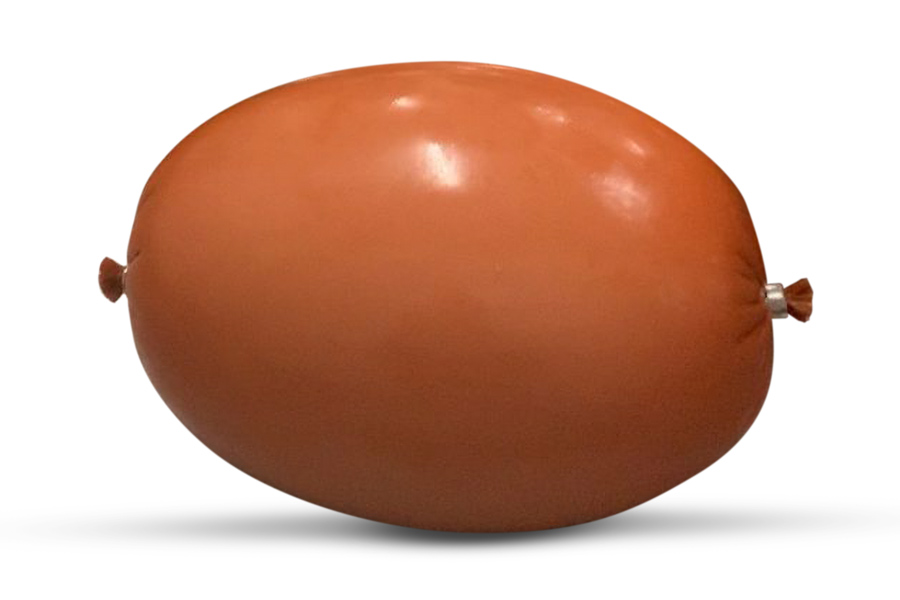

Our permeable plastic casings are made from advanced multilayer polymer films, specifically designed for the production of cooked and cured sausage products. Delivered as shirred, ready-to-use sticks, they are optimized for high-speed automatic machines, ensuring efficiency in modern sausage processing.

Thanks to their permeability, these casings allow proper curing while resisting mold formation, maintaining product quality throughout processing and storage.

Advantages of permeable plastic casings

Choosing our permeable plastic sausage casings provides key benefits for meat producers:

- High-speed processing with consistent results

- Microbiological resistance, preventing unwanted mold growth

- Superior mechanical strength and precise caliber control

- Color-marked options for easy identification of foreign bodies during peeling

- Multiple closed-end configurations to fit different production systems

- Full compliance with European food-contact regulations

Applications

Our permeable plastic tubular casings are ideal for:

- Cooked sausages

- Cured sausages and salami

- Processed meat products requiring controlled curing and durability

Why choose HS Casings

At HS Casings, we combine innovation, food safety, and efficiency to provide our clients with high-performance casings that optimize production while ensuring product integrity and consumer satisfaction. With decades of expertise and a commitment to quality and compliance, we are the trusted partner for sausage producers worldwide.